If you're planning on coming to the Come One Come All meeting on Friday Oct. 9th at 3pm, the location is the Mechanical Engineering building room 248.

Fabbers@UW

Monday, October 5, 2015

Come One Come All Meeting Location

Hey All,

If you're planning on coming to the Come One Come All meeting on Friday Oct. 9th at 3pm, the location is the Mechanical Engineering building room 248.

If you're planning on coming to the Come One Come All meeting on Friday Oct. 9th at 3pm, the location is the Mechanical Engineering building room 248.

Monday, September 28, 2015

WOOF3D Fall Kickoff

Greetings Printer Enthusiasts,

For UW students who are looking to learn more about WOOF3D and what we do or for students looking to get involved come to Dawg Daze Wednesday September 30th and Thursday October 1st from 10:00 am to 3:00 pm in Red Square. Look for us on Thursday October 8th 3:30 pm - 6:30pm at the Autumn Engineering Societies Fair in Maple Hall. If you can't make it to Dawg Daze or the Autumn Engineering Societies Fair and want to learn more make sure that you have time on Friday October 9th for WOOF3D's annual Come One Come All meeting at 3:00 pm location is TBD but keep checking in on our website (woof3d.net), facebook page (WOOF 3D) and around campus for flyers that will have updates!

If you already know about WOOF3D and are looking to join or are a former members there is now an online payment method to acquire membership in WOOF3D for a full school year. Check it out at (http://students.washington.edu/woof3d/join.html).

If you already know about WOOF3D and are looking to join or are a former members there is now an online payment method to acquire membership in WOOF3D for a full school year. Check it out at (http://students.washington.edu/woof3d/join.html).

Wednesday, September 23, 2015

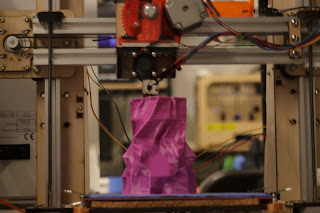

Our First 3D Printing Workshop for Teachers

This July we hosted our first half-day workshop covering “Beyond the Basics” 3D printing topics for teachers. The hands-on, three-hour workshop covered material including “Printing Difficult Parts” and “Printer Debugging”, focusing on teaching techniques and tools to teachers so they can better interact and maintain their 3D printer and focus on teaching instead of fighting with technology. The workshop serves to compliment the other training, support, and education initiatives we are doing to build resources for STEM/STEAM educators in the greater Seattle area. Of the ten teachers who attended, all left feeling the workshop was a valuable experience.

Slides and Handouts are (c) 2015 Ben Weiss, University of Washington and are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

|

| The hands-on portion of the workshop involved getting your hands dirty fixing a broken 3D printer. Photo credit: Steve Weidner |

We plan to offer the workshop again in the coming months, giving more teachers and students an opportunity to learn how to better use and maintain their 3D printer. If you are interested, please contact us at woof3d@uw.edu.

Slides and Handouts are (c) 2015 Ben Weiss, University of Washington and are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Monday, November 10, 2014

Mini-Lectures

Hi WOOFers and 3DP enthusiasts,

>Our first round of mini-lectures seemed like they were well received. Thanks to all who came out. Because some of you asked, I've posted links to the slides I used during my presentation:

3DP Toolchain Slides

3DP Electronics Slides

>I am doing another lecture this week: An Introduction to OpenSCAD. Everyone is invited!

For those of you who aren't familiar, OpenSCAD is a free, open source CAD package for 3D modeling.

There are many reasons why it's a great program to have in your repertoire of 3DP skills:

*If you're a beginner, OpenSCAD is simple enough to not be overwhelming.

During the course of the presentation I will be demonstrating the topics I cover within the OpenSCAD environment because I want you to see it in action. I encourage you to bring a laptop so you can follow along with me. If you choose to do this, before you come: A) make sure your computer is charged up so we're not fighting over outlets and B) download the most recent version of OpenSCAD here.

The lectures will be about 45 minutes and will start at 4:30 on Wednesday, 12 NOV with a repeat presentation at 4:30 on Friday, 14 NOV. They will be held in MEB 103.

I hope to see lots of enthusiastic faces there. Don't forget to be awesome.

-Mark H.

>Our first round of mini-lectures seemed like they were well received. Thanks to all who came out. Because some of you asked, I've posted links to the slides I used during my presentation:

3DP Toolchain Slides

3DP Electronics Slides

>I am doing another lecture this week: An Introduction to OpenSCAD. Everyone is invited!

For those of you who aren't familiar, OpenSCAD is a free, open source CAD package for 3D modeling.

There are many reasons why it's a great program to have in your repertoire of 3DP skills:

*If you're a beginner, OpenSCAD is simple enough to not be overwhelming.

*It can easily do some things other CAD packages cannot.

*It can be picked up pretty quickly (beginner or not).

*You will learn a different type of modeling, namely CSG (as opposed to feature based, direct, etc...).

*It is affordable. Each download is $0 and they give you a 20% bulk discount if you download ten or more.

*You help support the open source community.

*If you bought a Printrbot: there's an awful lot of satisfaction using a printer you assembled yourself when you're printing a part you designed yourself...During the course of the presentation I will be demonstrating the topics I cover within the OpenSCAD environment because I want you to see it in action. I encourage you to bring a laptop so you can follow along with me. If you choose to do this, before you come: A) make sure your computer is charged up so we're not fighting over outlets and B) download the most recent version of OpenSCAD here.

The lectures will be about 45 minutes and will start at 4:30 on Wednesday, 12 NOV with a repeat presentation at 4:30 on Friday, 14 NOV. They will be held in MEB 103.

I hope to see lots of enthusiastic faces there. Don't forget to be awesome.

-Mark H.

Tuesday, September 30, 2014

Come One Come All Meeting a Success

|

| New and potential members talking with WOOF officers in the workroom |

Monday, September 29, 2014

WOOF Come One Come All 2014 - 2015 3D Printing Club Introductory Meeting

Salutations 3D Printing Enthusiasts,

It

was our pleasure to meet all of you this week. In order to further

introduce you to our club we’d like to invite you to attend our

introductory “Come One Come All” meeting on Monday, Sept. 29th, at 5:00PM. The meeting will be held in the Mechanical Engineering Building in room MEB 246. There will be several opportunities presented at the meeting:

First,

we’ll introduce you to the Printrbot Simple. This is the printer kit

we’ll be offering this quarter. It’s a nice little printer and assembles

very quickly. Everyone that orders one through the club will get special work times set aside to put the printer kits together with the aid of WOOF officers.

Second,

we’ll be introducing our projects for this year. If you are interested

in design, mechanics of printers, large format printing, printing in

composite materials, writing code, electronics, or control systems,

we’ll introduce you to the projects we have planned. If you have an idea

of your own, you could also start your own project and we’ll help you

form a team to take it on. Once the meeting is over, you can group up

and speak with project leads about anything you are interested in.

Third,

the money. Membership dues are $20 for a year, renewing in September.

So if you think you may want to join us, or you are renewing your

membership, bring $20 cash to the meeting. If you won’t have a twenty on Monday,

it’s no big deal, you can contact us to pay at another time. If you are

interested in a Printrbot, we’ll be taking payment for those kits at a

later date.

Fourth, we’ll have a quick optional “How to Get into 3D Printing” lecture 15 minutes before the meeting at 4:45. This will be a first of a series of optional mini-lectures to help you jump into the technology.

Thank you for your time and have a great weekend!

Washington Open Object Fabricators

P.S. Any questions can be directed to woof3d@uw.edu

Friday, September 26, 2014

WOOF Successful Outreach at UW Dawg Daze

|

| Jeff and Kim at the WOOF booth |

Wednesday and Thursday September 24th and 25th

WOOF participated in the University of Washington’s annual First Year Programs

Dawg Daze (http://www.uwdawgdaze.com/) held in Red Square. In wind and rain, WOOF used the opportunity to introduce interested students to some

of WOOF’s projects, encourage them to sign up for the mailing list and to

attend the upcoming “Come One Come All” meeting. On display were a collection

of 3D objects printed in a variety of materials such as poly lactic acid (PLA),

a carbon fiber composite PLA and recycled HDPE. Running off of a 12 volt Fire Engine battery and a power inverter was this year's printer kit - the Printrbot - offered for sale to anyone interested in building their own 3D printer. Enthusiasm for the club was high

with 290 students expressing interest. WOOF welcomes new members from all

backgrounds and levels of experience. Anyone is welcome to drop by the WOOF room - Room G045 on the ground floor (almost the basement) of the UW's Mechanical Engineering Building (MEB G045).

|

| Printrbot, filament, and objects printed and cast in different materials: PLA, Carbon Fiber Composite PLA and Brass |

Saturday, August 30, 2014

WOOF Members Attend 3D Printer World Expo in Bellevue

Friday August 22, 2014

WOOF members had the opportunity to

attend the 3D Printer World Expo held at the Bellevue Regency Hyatt in Bellevue

WA. 3D Printer World Expo Bellevue, WA Aug 22-23, 2014

The Expo was well attended and the 3d Printer research, design and

manufacturing communities were well represented. University of Washington Mechanical Engineering Professor

Mark Ganter, one of WOOF’s faculty advisers, gave a presentation on 3D printing

materials sustainability. After Friday’s

closure, Professor Ganter accompanied a group of WOOF’s officers to the

Cheesecake Factory in Bellevue.

When asked about the experience, WOOF Officer Mark Hanson stated “For me, it was exciting to see the innovations people have made in the consumer market. I loved comparing the various ways people are doing more with less as we continue to perfect these machines.”

This experience helped bring WOOF onto a broader playing

field and allowed WOOF to connect and catch up with current 3D Printer

innovators like Lulzbot, Makerbot, Matter Hackers, Flashforge and Leapfrog.

HDPE Print Bed Adhesion Solution

3D printing using recycled HDPE (shredded

gallon milk jug flakes) comes with many challenges, one of them being print bed

adhesion. HDPE has become infamous to WOOF for its uncontrolled

warping and shrinking, which causes prints to peel off of the print bed. To

mitigate this, WOOF Officer Brandon Bowman began developing a process to create

an HDPE print surface.

The initial idea was to heat gun

HDPE flakes onto steel plates (18” X 18” X 1/8"). This evolved into baking

using a standard baking oven. Bowman initially baked HDPE flake onto a

steel plate then applied force on top of the flake using another surface, his body weight and his feet.

This process

produced inconsistent and non-optimal results. Size limits of the baking

oven, the need to put plastic in an oven, and the need to apply spray on Teflon

coating encouraged designing a different solution.

Over time the flake baking process

evolved into a recipe reasonably perfected by WOOF’s Director of Operations Dana

Henshaw. The following recipe utilizing a Wabash Hot Press

has produced promising results:

Stack

4 plates prepared in the below manner with a 5th steel plate by itself as a

barrier on top into a hot press.

To

prepare each steel plate requires:

1

- 24” X 24” Steel Plate (1/8” thick)

3

- Pints of Recycled HDPE Milk Jug Flakes (cleaned and shredded) spread on the steel plate leaving an approximately 1" border.

1 – 24” X 24” Sheet of Porous Teflon Coated Fabric

1

– 24” X 24” Sheet of Breather Material

Finally top the sheet off with:

Then using a Hot Press:

Apply

and maintain 400lbs of force

Increase

temperature to 375 °F over 30 minutes

Hold

at 375 °F for 40 minutes

Cool

for 10 – 20 minutes

Remove

the 400lbs of force and separate hot press platens

Then

carefully remove the hot plates

After the plates are cooled, they are attached to the build surface and then used for printing.

This is an attempt to print a cylinder that was to be used as a potential floatation device.

This turned out to be a great learning experience. Here are a few things that were tried but did not work:

Failure of first hot press: Used

only non-porous Teflon coated fabric. It made sheets that were too smooth, and

the first layer of printed HDPE wouldn't adhere well enough.

Failure of second hot press: holding

pressure for 20 minutes with the breather material was not long enough for

temperature to penetrate deep enough into the stack to allow full adhesion of HDPE flake onto

each plate. The HDPE on the middle plates stayed as flakes.

In all, developing this process has allowed

the WOOF team to achieve successful prints of the sections a multi-sectioned

Kayak.

Subscribe to:

Posts (Atom)